Warehouse optimization is the process in which the use of time, space, and resources in a warehouse is made more efficient through automation and careful planning, improving customer satisfaction and experience.

It is the continuous process of making changes, such as implementing modern technology and automating tasks, to help a warehouse run at peak efficiency.

Warehousing helps businesses maximize their inventory capacity and accelerate the flow of products, which in turn can drive sales and increase customer satisfaction.

Benefits of Optimizing Warehousing

Warehousing provides numerous advantages that could dramatically enhance the effectiveness of warehouse processes.

Improved Inventory Management

Managing inventory is a complex job, especially when a business juggles hundreds — or maybe even thousands of stock keeping units.

Optimizing warehouse operations could enhance the precision and efficiency of the management of inventory.

Enhance Productivity

By better sorting inventory, applying effective strategies for picking, and using automatic systems, the operations could manage a lot more transactions quicker and with less mistakes.

This means there’s an efficient flow of items and faster response times, which is important for meeting deadlines in production and making sure operations run smoothly.

Better Employee Safety

Optimizing operations in the warehouse can help enhance employee safety because there would be a reduction in the need for heavy work jobs, like lifting heavy items.

Enhanced Precision and Order Fulfillment

Warehouse optimization makes sure that the right items are picked, packed, and shipped effectively and accurately. This means there are fewer errors during order fulfillment, meaning less need for exchanges or returns and improving the overall experience of the customer.

Optimized Utilization of Resources on Labor

By simplifying warehouse operations and integrating automation where needed, businesses could optimize where labor resources are allocated. This enables employees to move their focus on higher-value jobs, like quality control or even customer service, instead of wasting time on doing manual tasks repetitively. It also improves job satisfaction as well as the morale among the staff.

Improved Customer Experience

An optimized warehouse dramatically boosts the experience of the customer by making sure that goods are available when they’re needed and can reach customers in the expected timeframe and condition. Accurate records help avoid backorders and stockouts, while streamlined procedures reduce delays in shipping.

Strategies for Faster and Smarter Operations

Assess & Understand Your Current Warehouse Setup

You can look at this stage as if it’s a diagnostic test; needed improvements will be indicated by the results.

You may discover a chance to better sort your warehouse, spend money on new equipment, or even upgrade shelving systems and warehousing racks. Whatever it might be, this initial review is the roadmap for needed changes.

Set Objectives & Pain Points

Specific objectives will provide purpose and direction, letting you better plan out the strategy.

It’s in this stage where you need to remember to prioritize the customer. If one of the goals is cost reduction for instance, but in turn it compromises the accuracy or speed of shipping, you may indirectly affect the customer experience negatively.

Get Your Inventory Management Right

Once the assessment of your current setup is finished and you’ve identified your goals, the initial warehouse function that needs to be optimized is the inventory management system. From holding costs reduction to improving the flow of cash, the right techniques for inventory control and systems could significantly improve the effectiveness of your warehouse.

Utilize A Warehouse Management Solution (WMS)

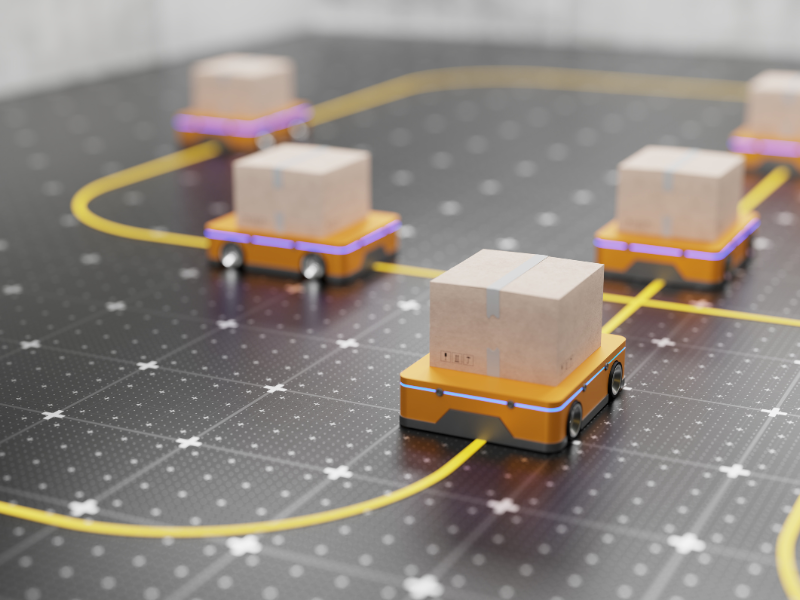

A good warehouse management system (WMS) utilizes data and makes many of the tasks automated, tasks that would otherwise be heady duty with margins of error (such as shipping, receiving, storage, kitting, picking, packing, etc.).

Warehouse management solutions streamline these procedures and provide a single root of truth, so you don’t need to guess or cross-reference a number of systems to find out what’s happening with your warehouse.

Invest In Training Staff

A warehouse can only be as efficient as the least-trained employee. Not properly training employees means they won’t do tasks to the best of their abilities.

Conclusion

Optimizing warehouse operations is essential for businesses aiming to improve efficiency, reduce costs, and enhance customer satisfaction. By implementing automation, adopting a warehouse management system, and streamlining inventory control, companies can boost productivity and accuracy while ensuring a safer work environment.

Investing in staff training and continuously assessing warehouse performance will keep operations running smoothly. A well-optimized warehouse not only enhances supply chain efficiency but also drives long-term business success.